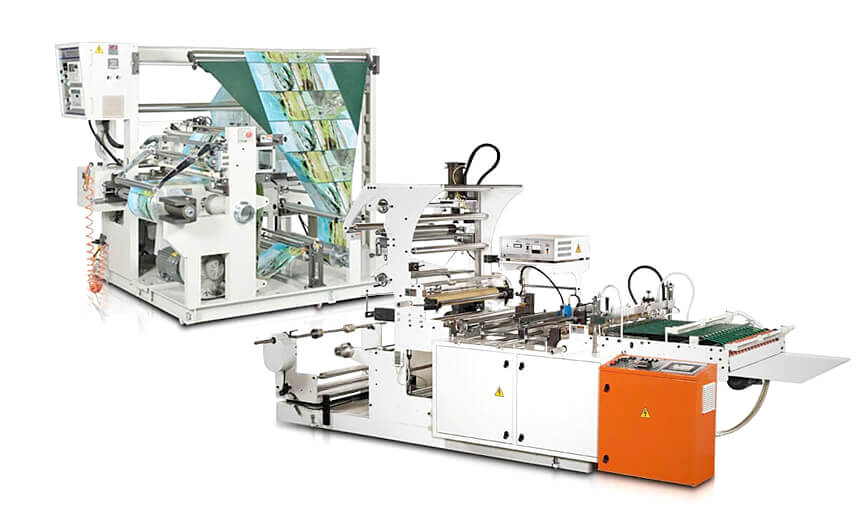

Side Sealing Machine Auxiliary Equipment SDH-263SF

-

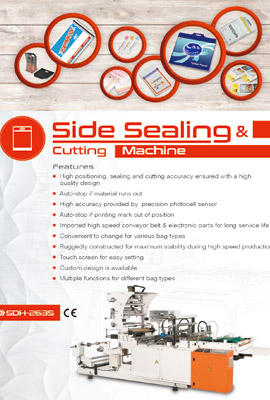

Product features

- - High precision cutting control provided by servo motor device.

- - This plastic side sealing bag making machine have auto stop function if material runs out.

- - High accuracy of pivot points tracing provided by advanced high precision photocell sensor.

- - Auto stop if printing mark out of the right position.

- - Imported high speed conveyor belt & electronic parts for longer life of the bag on roll device.

- - Convenient to change for various shapes and sizes of poly bag.

- - Ruggedly constructed for maximum stability during high speed operation.

- - Can be customized into an automatic plastic machinery for PP, OPP, CPP, LDPE, HDPE poly material T shirt bag, bread bag, cloth bag, nylon bag making.

Optional equipment- - Round hole punching device.

- - Butterfly (Euro hole) puncher.

- - Auto conveyor table.

- - Advanced Edge positioning controller(EPC).

- - Heating line device.

- - Vertical continuous sealing device.

- - Poly Bag dividing device.

- - Glue applicator.

- - Glue skip.

- - Ultrasonic longitudinal sealing device.

- - In line triangle v-type folding device.

- - Auto Hanger insert device.

- - Related equipment required for poly mailer machine.

Global Plastic Bag Folding Machine Manufacturer

Based on 30 years of manufacturing experience on the single layer side sealing bag making machine& T shirt bag making machine in Taiwan industry, such as the most advanced manufacturing technology on the garbage bag making machine, we can manufacture a variety of auxiliary equipment of the machine plastic bag manufacturing plant. Each machine is equipped with a digital control panel screen and provides customized design service to manufacturers around the world. S-DAI Industrial company is one of the global v-type trianglar bag converting machinery manufacturers and suppliers in Taiwan, providing highly customized poly bags machinery production line and other related plastic bags maker auxiliary products powered by servo control to United Sates, Canada, Mexico, Argentina, Ecuador, Colombia, Guatemala, Belize, Dominican Republic, El Salvador, Panama, Peru and Chile, and many other countries in Europe, Africa and Asia, such as Russia, Ukraine, Poland, Hungary, Romania, Bulgaria, Serbia, Croatia, Slovenia, Slovakia, Greece, Italy, France, Germany, Spain, United Kingdom, Portgaul, Egypt, Nigeria, Ghana, Kenya, Algeria, South Africa, Australia, India, Bangladesh, Sri Lanka, Indonesia, Thailand, Vietnam, Uzbekistan, Turkey and Saudi Arabia. If you are interested in this bags making machinery related equipment, welcome to watch the detailed introduction of this double up machine production lines on YouTube, and follow our latest video information. Every time when we take new customized project just is an opportunity for us to improve our manufacturing and design. With more than 30 years of manufacturing experience, we can design and manufacture the most user-friendly automation and digital sign management models for auxiliary equipment and machinery for plastic bag manufacturing. In the past 40 years, we have provided related machinery manufacturing services to the world, which can make precise folding of plastic film, align each cut, and smooth material feeding. We can provide you with solutions that can meet your needs and touch your heart.

Over 30 Years Experience on Plastic Bag Auxiliary Equipment

Base on over 35 years experience of manufacturing standard fully automatic plastic bag making machines, side sealing bag machine, bottom sealing bag machine, T shirt bag making machine bag, and film packaging & keaft paper machinery, have extensive experience in handling the tension and strong sealing of thick or thin plastic bag, we can design and manufacture the top quality sandwich v type converting machinery that could fold each one plastic seal bag in a accurate way, not just a semi automatic outdated design. S-DAI provides you with the best customized folding design, which is not only suitable for your other devices, but also provides an excellent processing solution for all flat films. In addition to manufacturing capabilities on advanced v-type converting machinery and rewinding device, S-DAI also can make a special perfect 3 or 4 replicating bag on roll processing combination system of hot heat sealing, cutting and punching for the most energy efficient and high speed production on various sizes PP, OPP, CPP, LDPE, HDPE t-shirt bag, garbage bag, bread bag, cloth bag and many others poly material nylon bag. SDH-263SF is our main customized automatic bag machinery model of auto side sealing, cutting all in one system making machinery line by servo motors control, and can also be integrated with packing and other printing optional equipment for many other new industrial applications. This machine model can customize the converting mechanism for all folds on the film, and can cooperate with the connected poly bag making machine to adjust the output speed of the folded film. If you click on the above video, you will find the smart design of this machine for manpower saving. This equipment can choose to add a special mechanical device to save manpower at the raw material input. The input and placement of film materials can be completed at the profile of this equipment without more than 2 people and carts.

-

Model SDH-263SF Available Material PP, OPP, CPP, LDPE, HDPE Width of Bag 50 - 600 mm Length of Bag (no min) Max.600 mm Speed pc minute

(Depends on material, bag type and size)(no min) Max. 200 Thickness

(Depends on material type)0.015~0.08 mm Heater 2 kW Motor 1.5 HP Power Required 5.5 kW Packing Dimensions

(L×W×H)310 × 145 × 205 cm Weight N.W.: 1220 kg

G.W.: 1520 kg

*Specifications are subject to change without notice.*This combo machinery production line with servo system the model number will with (NC)

-